From the dawn of the world, we – human beings tend to slip into comfy pieces of cloth and gussy up for special occasions. To cater to that need, people formed a variety of departments in a factory to mass produce and hand out beautiful garments to consumers. In this article, we will introduce different departments functions in a garment factory via a process flowchart so you can understand how they do it.

All teams have their own responsibilities and activities to reach a common goal which is to develop the business of the garment factory. In this article, we will learn more about the tasks that each department must complete.

19 Departments And Its Functions At A Garment Factory

1 Marketing department

In simple words, the marketing department is the face of the factory. While the other departments will take care of the production of the goods, the marketing team will be responsible for the development of the company’s business.

- They will reach out to potential customers to persuade them to become new customers while maintaining relationships with old customers of the company. The team will make sure what the customers receive will exceed their expectations. As a result, the company retains customers and makes them marketer for you.

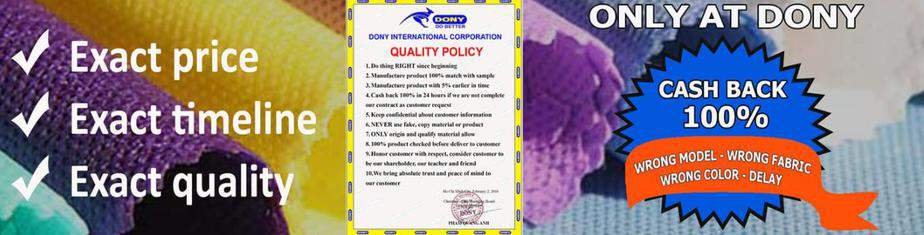

- Marketing department will use specific methods to make the company’s products more attractive to the demanding eyes of buyers. The company will sell like crazy when we showcase our design capability, factory compliance, and quality policy as it helps the company become trustworthy.

2 Design department

The designers team are responsible for research and development of new and trendy fashion models. In terms of products, this helps increase the reputation of the factory as it creates or follows the biggest fashion trend.

- Every season, the team will focus on delivering new fashionable designs to show-off the strength of the factory.

- They always own a library for fabrics, trims and accessories, and for garments.

3 Merchandising Department

In short, the merchandising department will receive orders from the buyer and satisfy their need to try out samples.The department employees will estimate materials and processing cost and inform those who are interested. This team also has to follow up the production status.

In a large factory, the merchandising team is divided into two groups: Sampling merchants and production merchants. Sampling merchants organize activities and exchange information related to sample garment for buyers. Production merchants process volume production orders, devise production plans, survey supply prices, and keep track on production status.

Activities of this department include:

- Exchanging information with buyers

- Review and develop samples

- Indicate the cost of the product

- keep goodwill with customers

- pre- and post-production planning

- Preparing Bill of Material (BOM) and fabric indent

- Source of raw materials

- Quality confirmation

- Elaborate Production File

- Run the Pre-Production Meeting

- Execute orders

- Providing customer care

4 Pattern Making Department

In order to produce beautiful clothing patterns, factories will hire pattern masters to create garment patterns and digitize them into CAD (Computer Aided Design). The activities of this team include:

- Making and Grading Pattern

- Works on Samples

- Check and modify the product to match the standard output

- Editing products based on customer feedback

- Design a sample design prior to mass production

- Calculate the amount of fabric required to mass produce clothings

- Increase marker efficiency to decrease wasted fabric

5 Sampling department

Each time the buyer needs to test the goods, members of the sampling department are responsible for sending samples, handling customer feedback and informing the customer’s request to the production department.

- Understanding the garment specs and workmanship of the garment.

- Help with quotes for customers

- Estimate the amount of fabric needed

- Fully complete the cutting, stitching, finishing and inspection steps to produce the prototype for the customer. Then make a detailed report on the sample to the customer

- Perform the fabric shrinkage test

- Coordinate with the production team to correct the inadequacies and make the complete clothing style

6 Fabric Storing department

They are the people who store a large amount of fabric for the cutting department

They have the following duties:

- Contact and understand your factory’s fabric supplies

- Receive and store fabrics in bulk, manage fabrics inventory record

- Check the untreated fabric and the treated fabric

- Elaborate shade band for colored and printed fabric

- Test fabrics physical properties

- Fabric Issue

- Fabric printing

- Track what fabric is used for

7 Trims and Accessory Storage

Glamorous ornaments on dresses and suits are an indispensable part to enjoy a perfect grande soirée. Usually the person in charge of this task is also the member of the fabric storage department.

- Find the supplier for all kinds of materials like sewing thread and accessories to make trims

- Quality control and quantity of trims and accessories

- Preserve and preserve quality trims available

- Handling problems related to reserves

- Dye the twill tape

- Arrange and deliver trims to the requesting party..

8 Production Planning and Control department

As its name suggests, this department is responsible for planning and ordering the order processing. The work of the PPC department is intimately tied to all production processes. The components will be scheduled for processing in the production plan to keep up with the work progress. If the size of the factory is small, the department will be merged with the merchandising department.

Production Planning and Control department of large factories has the following duties:

- Scheduling tasks for the workforce

- Ask the storage for raw materials

- Loading Production

- Plan and execute production

- Location of the establishment

- Evaluating the amount of product and fees of production

- Perform estimation on the production capacity

- Plan ahead for the production line

- Production follow up and execution

9 Cutting department

This is the department that will execute the cutting of large fabrics into sizes for reassembly at the sewing department.

This team will do:

- Obtain and process fabric softeners from the factory’s storage

- Cut and lay the fabric into layers

- Maximize the amount of fabric used and reduce the amount of fabric wasted when cut

- Sort, sort, count the number of pieces of clothing

- Inspect the fabric cut

- Sorted and cut printed and embroidery panels

- Fusing individual parts of the garment

10 Sewing department

After receiving the processed fabric at the cutting department, the sewing floor will assemble the fabric into clothes through a chain of production. So their work includes:

- Production line installation, inspection and maintenance

- Sew the parts of the garment together

- Maximum amount of fabric used in sewing

- Iron the parts of garment

- Make changes to the sew way to make the garment more beautiful

- Check the quality of sewing parts made of sewing

- Take notes to track the production of your product

11 Machine Maintenance Department

This is a technical department that will take care of any problems related to sewing machines. Their tasks are:

- Establishing the sewing machines

- Maintaining and fixing the sewing machines and equipment

12 Industrial Engineering department

This section of the factory will monitor, coordinate and increase production line performance. You will need industrial engineers to carry out specialized tasks of the department. In a factory, the engineering department is responsible as an overseer to control the production situation through the following activities:

- Calculate the Standard Allowed Minute (SAM) to figure out the production cost.

- Calculate the amount of sewing thread required to produce a shipment.

- Analyze and give a solution to an order

- Provides a way to use machines and workforce for an operation to run smoothly

- Improve factory efficiency through method studies, time to finish an order and factory capacity

- Production line coordination

- Labor cost calculation, operating cost

- Research and develop production methods in detail

- Storing information about production methods

- Control production

13 Washing department

The department has one job is to remove the dust and tracing mark on the stitched garments. This is a required work on samples and finished products because it will give a fresh look to the clothes

14 Finishing department

This department ensures that output will be in its finest look through the following jobs:

- Trimming the extra thread on the clothes

- Attaching, polishing buttons on garments

- Remove the stain and ironing the garment

- Folding and packaging the finished product

- Check and feedback to other departments of the production chain

15 Quality Control department

They are responsible for ensuring the garments are qualified to be placed on the market

- Create standards for output products

- Give a set of step-by-step instructions to help workers carry out routine operations

- Quality Assurance

- Eliminate items that do not meet standards

- Make sure the quality of the fabric received by the cutting department is the fabric without defects. If there is a minor error in the fabric, this department will mark it up and give the solution to the cutting department

- Reporting and conducting meeting on output product quality

16 Accounts department activities

- Pay salary, manage the company’s account

- Make advance payment, recompense payment for production costs

- Collection of debts on buyers

17 Human Resource and Administration

- Recruit new employee and ensure social welfare of employees

- Keep a record of the employees who worked at the factory

- Take care of labor issues

- Receive feedback from employees on labor status

- Guide newcomers to work at the company

18 Electronic Data Processing (EDP)

They work on the software and computer system of the company

- Buy and maintain working computer systems

- Ensuring smooth mail system and internet

- Implementation of security, maintenance of the company’s computer systems and databases

19 Shipping and documentation

They make deliveries on request of other departments. They are the ones bringing shipments to buyers as soon as possible. They are also responsible for archiving related correspondence.

Where do I find a fully set up factory?

Dony Garment Vietnam is one of the leading manufacturers in the field of clothing production in Vietnam. With a professional team and facilities, we manufacture high quality clothing products at reasonable prices. At Dony, you’re more than just a number on our sales page. You are a friend that we sincerely respect and we will work tirelessly to build lifelong relationships with you.

In conclusion

We all love comfy pajamas, daily casual outfits and fancy schmancy suits and ties. All these types of clothing are the fruit of a complex process that starts with researching and developing and ends after delivering the finished product to the consumers.

Follow us to find out more information about garment production. If you need to make any orders, please contact DONY Garment now to manufacture high-quality products that’s second to none.

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment

This year, we have found that many international buyers are seeking new suppliers based in nations outside of China and Thailand to purchase many goods and products, including uniforms, workwear, reusable cloth face mask, and protective clothing.

At DONY Garment, we are proud to welcome international customers, especially those based in the US, Canada, the Middle East, and the EU market to discover the professional production line at our factory in Vietnam.

We guarantee our products are of the highest quality, at an affordable cost, and easy to transport across the world.

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Please write more about jobs in the fashion industry, like:

+ Fibre processing (developing the natural fibres, creating the man-made ones)

+ Trend forecasters

+ Textile designer (dyeing, weaving and knitting)

+ Fashion designer

+ Pattern cutters

+ Graders

+ Seamstresses

+ Fashion illustrators

+ Fashion photographer

+ Fashion buyers

+ Fashion merchandisers

+ Fashion stylists

+ Fashion marketers

+ Fashion sales