1 Introduction

If you are starting your own fashion brand, it’s crucial to do a lot of research on your potential manufacturers, starting with the comparison between CMT vs fully factored manufacturing in the apparel industry. This article will give you a better view regarding this topic.

2 What Is CMT Manufacturing?

First of all, CMT stands for Cut – Make – Trim. It is a factory that turns your ideas into finished products.

In the making process, the company will cut and sew the garment and provide the finishing touches. But before that, they will need your specs, textiles, layouts, and stitching needs.

Brands that already have a small range of products will benefit the most from this option. Most CMT manufacturers demand lower order quantities and offer greater versatility.

3 What Is Fully Factored Manufacturing?

As the name implies, you will receive a complete service from the manufacturer. They build designs, select fabrics, and create samples. All in all, they will carry you all the way through garment production.

Fully factored manufacturers handle everything from development to delivery process. For a designer with little or no experience, this type of manufacturer is the best option.

These providers recognize that their customers are new in the apparel industry; thus, eager to help them in all aspects of production.

Expect to answer countless questions and have many discussions before starting the process with a fully factored manufacturing.

4 What Is The Difference Between CMT vs Fully Factored Manufacturing In Apparel Industry?

Costs

Even though it may appear that a fully factored is the more expensive option, it is not always the case. The CMT manufacturer will add in the time to get materials and manage the shipping process.

If you don’t have any experience, you will risk incurring expenditures. Any concerns will need your engagement, which will take time away. Finally, the consequences of mistakes are usually borne by the consumers.

Experience And Knowledge

A fully factored manufacturer has the required experience and contacts in the industry to ensure flawless functioning. The company will also handle and guide clients who are unfamiliar with the process.

Location

Many garment producers are in different locations other than developing countries. Keep in mind that a CMT manufacturer involves close collaboration with the supplier.

Size Range

The product’s size range is also very important. A CMT manufacturer is suitable for small businesses, usually accepting a lower average order rule.

Medium to big companies will benefit more from fully factored manufacturers. They can handle larger productions; consequently, decreasing the cost per unit of manufacturing.

Foresight

When deciding between a fully factored manufacturer and a CMT, you will need to consider the foresight of each one.

Cooperating with the former, you need to be able to rely on your source completely. Since they do the majority of the work, you won’t have as much influence with this alternative.

Meanwhile, CMT manufacturers do not manage all responsibilities. You can have better insight into the entire process.

Controllability

CMT manufacturing may be the best option for you if you want to know what’s going on with your operation. On the other hand, a fully factored manufacturer is in charge of the entire procedure.

5 CMT Manufacturing’s Advantages And Disadvantages

Advantages

Lower Order Quantities

More established companies will require stricter order requirements. When sourcing the fabric yourself with a CMT manufacturer, you are not bound by minimums. It means it gives you more alternatives, greater flexibility, and a lower cost.

Better Insight

A CMT manufacturer will give you complete control and insight into your production. You will know exactly where every element comes from and can inform your customers about it.

Meeting Your Expectations

When working with a CMT manufacturer, you acquire exactly what you’re seeking. It means you can make fewer compromises since you will select your preferred material.

The fully factored manufacturer’s supplier relies on previous connections. Sometimes, you won’t be able to find what you want, or the quality won’t satisfy your expectations.

Waste Reduction

Because there is more control over material usage, CMT is a responsible alternative.

Disadvantages

Cost

Using a CMT manufacturer is usually a more expensive choice. The cost can add up when you are paying for materials, delivery, taxes, and customs.

Plus, they will have to outsource partners for some customary requirements. It will also increase the cost and processing time.

Delays

There are many variables that may influence the processing time, including materials stuck, false designs, or wrong shipping locations. Thus, it’s impossible to predict any delay.

Fully factored manufacturers usually have direct material suppliers and can resolve issues better.

Development

CMT is suitable for smaller brands but can’t guarantee keeping up with the growing demands. They may experience different challenges or be unable to offer more favorable arrangements.

6 Fully Factored Manufacturing’s Advantages And Disadvantages

Advantages

Full Service

The factory looks after all procurement and production. It means that you won’t need to manage your supply chain or worry about lots of extra payments. They will also nominate a suitable material’s supplier.

Economical

Fully factored manufacturers are the best value option. They only need you to meet the minimum order requirements.

Fewer To No Delays

Fully factored manufacturers have distinct sections in the making process. For example, procuring materials, inspecting, managing imports and exports, and logistics. The company will correct any errors or inconveniences.

Better Offshore Manufacturing

Handling delivery in different countries with a CMT manufacturer might be difficult, but fully factored manufacturers will know exactly what they need to do since they are familiar with the local laws and taxes.

Disadvantages

Higher-Order Quantities

Fully factored manufacturers will mostly demand large order quantities. It can be hard if you are on a budget or left with many unsold products.

Limited Flexibility And Insight

The downside of a fully factored manufacturer is that you have less flexibility. Your insight into the process is also limited. It will also be more complicated to figure out where your materials come from.

7 Final Thought

When settling on a production line, inexperienced entrepreneurs must assess their possibilities. The difference between CMT vs fully factored manufacturing in the apparel industry isn’t complicated. After figuring it out, you will be able to narrow down your options.

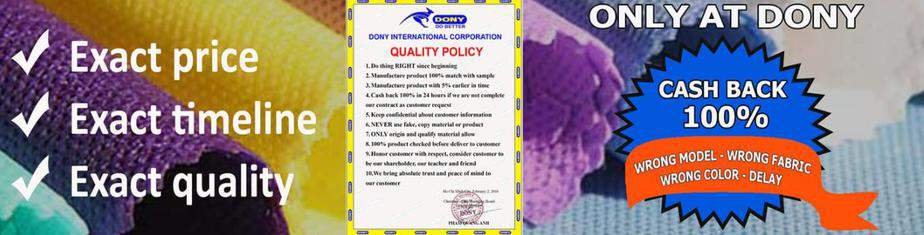

If you haven’t figured out what is the best for your brand, you might want to consider Dony Garment Company.

Dony Garment is a garment/clothing manufacturer based in Vietnam. Dony Garment well-known for creating high-quality products at a lower-than-average cost.

With many years of experience, DONY are capable of providing great services, before, during, and after the purchase. Whether you’re a small business or a big company, you can go for Dony Garment.

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment

This year, we have found that many international buyers are seeking new suppliers based in nations outside of China and Thailand to purchase many goods and products, including uniforms, workwear, reusable cloth face mask, and protective clothing.

At DONY Garment, we are proud to welcome international customers, especially those based in the US, Canada, the Middle East, and the EU market to discover the professional production line at our factory in Vietnam.

We guarantee our products are of the highest quality, at an affordable cost, and easy to transport across the world.

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment