CMT is a manufacturing service provided by factories that essentially cut, make and trim your designs into fully produced products. The factory will require specifications, patterns, fabrics, tech packs, fabrics, and stitching requirements from you before production.

CMT is a term in the cloth and apparel industry that stands for Cut, Make and Trim. The various terms are explained as thus:

The cutting involves the use of various equipment and technology to cut out designs and patterns on the fabric depending on the specifications provided. Special machines are used to make a precision cut.

The next stage is the making. Here manufacturers use advanced machines as well to stitch the materials together to create the final product.

The last stage is the trim. Here the manufacturers conduct thorough quality check on the finished products to ensure that it is perfect and okay for shipping to the buyer.

CMT is also a business term used in pricing in the clothing industry. Usually, the company purchasing the apparel would pay the manufacturing company to carry out the cut-make-trim process.

The various processes such as the processing of the order, the development of the product, the grading and designing of patterns are done before production begins. While other processes which include the shipping of the final products are handled by the buyer.

There are different methods for the manufacturing of garments used by different manufacturers, yet the CMT, despite how old, is a more preferred process used by different apparel buyers.

Usually, the buyers provide the fabric used by the manufacturers. They provide their choice of fabric and trims that are to be used by the CMT garment manufacturers. This means that there is no need for the factory to go through the whole pre-production process or the development of samples. They would just focus basically on the production of the apparel.

You can check out other posts that provides details on the cutting, stitching and the finishing process.

Advantages of using CMT to a brand.

The CMT production process is of benefit to different brands because it enables them to select their fabric. The brands can easily determine the right quality fabric they intend to use. Fabrics are very expensive so it is importnt selecting the right quality of fabric based on certain features provided by different well-known mills. It also has economic benefit as the brand can save cost by purchasing the fabrics themselves.

The CMT is also beneficial to brands in that the buyers can control how the cloth is manufactured and the way the apparel is sourced. Most buyers set up a functional team that sources quality fabrics and develop a good rapport with fabric mills. Since the CMT price is open to anyone, Manufacturers would charge lower at the margins and can’t manipulate the overhead pricing or how they material.

Advantages of the CMT Manufacturing to the Manufacturers.

Using this method, the CMT manufacturers can easily manage a small staff as their overhead activities are reduced to the minimum.

Manufacturers do not need to invest too much capital into buying fabric or the purchase of raw materials. The cost of running the factory is also reduced. Factories can also charge buyers for the trims.

Business analysis as regard cost and benefit can be easily performed for a CMT business as it is less complicated.

The manufacturers can’t be held responsible for the quality of the materials or fabric since they are supplied with these by the buyer.

The CMT manufacturers would not also charge much since there are no overhead cost or any hidden manufacturing expenses.

The full package apparel manufacturers (FOB order processing) handle the development of the product, sampling, production as well as shipping of the garment up to the port in the case of export orders.

It might interest you to know that so many sportswear brands get their materials and apparels from CMT manufacturing.

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment

This year, we have found that many international buyers are seeking new suppliers based in nations outside of China and Thailand to purchase many goods and products, including uniforms, workwear, reusable cloth face mask, and protective clothing.

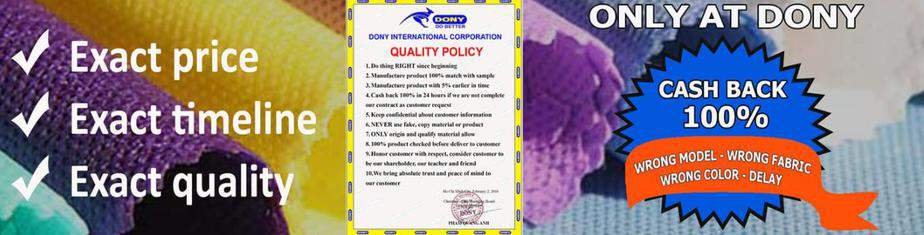

At DONY Garment, we are proud to welcome international customers, especially those based in the US, Canada, the Middle East, and the EU market to discover the professional production line at our factory in Vietnam.

We guarantee our products are of the highest quality, at an affordable cost, and easy to transport across the world.

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment