Among the many garment manufacturing companies in Laos, this article has been aimed to provide you with a short list of the most affordable and reliable manufacturers. This article also provides you with a few points that you should take into account when choosing a manufacturer to work with.

1 Forced child labor

During the reporting period, the Government of Laos increased its efforts to combat forced child labor in garment manufacturing companies in Laos and abroad. The Government of Laos also implemented new awareness-raising activities in areas with a high prevalence of trafficking.

It increased its efforts to identify, protect and remove victims of human trafficking, particularly in the southern part of the country. It provided unspecified funding for these anti-trafficking activities.

During the pandemic, the Government of Laos improved the effectiveness of its law enforcement capacity to investigate and prosecute traffickers. It improved the criminal code to more effectively prosecute traffickers for child sex violations. It continued to utilize a victim identification manual in coordination with international organizations. It increased the number of trafficking convictions.

The Government of Laos also increased its efforts to reintegrate victims. It supported the repatriation of 220 Lao women and girls who were victims of forced or fraudulent marriage in the PRC. It also worked with international counterparts to repatriate workers from the Golden Triangle SEZ. It also increased the monitoring and oversight of labor recruitment in highly vulnerable SEZs.

The Government of Laos maintained bilateral labor agreements with several common destination countries. It responded to public outcry over working conditions in one BRI site. It also improved the conditions of labor in some SEZs. It renegotiated its bilateral anti-trafficking agreement with Thailand in 2021. The previous agreement was time-consuming and costly for workers. It was complicated and reportedly caused many Lao migrants to opt for irregular migration channels.

In addition, the Government of Laos did not report on the number of trafficking victims who declined official assistance. It did not provide updated information on civil registration procedures during the pandemic.

2 Poor working conditions

Despite the fact that the garment industry in Laos has been one of the most successful sectors in the country’s rapid development, it has also been criticized for poor working conditions. This has prompted progressive politicians to campaign for new laws. Some workers have complained about the quality of drinking water, air conditioning, and sanitation facilities in factories.

The anti-sweatshop movement has led to the regulation of workplace safety. Many companies have agreed to reduce the use of dangerous chemicals and reduce employees’ working hours. Among the most notable examples are Nike and Gap.

The World Bank has released a report on the garment industry in Laos. It has found that attrition rates at large and medium firms in the country are around 3.5 percent every month.

The report, entitled World Bank Report 70809-LA, is based on a survey of workers and managers. It was funded by the World Bank’s Gender Action Plan and the Lao PDR Trade Development Facility, which is financed by Australia, Germany, and the European Union. The report was presented at the ILO/IFC Better Work Conference in Washington, DC.

The study surveyed a sample of 333 workers and managers in three garment factories in Vientiane, Laos. The survey was conducted using the LISREL software 9.30 for Windows. The questionnaires included key informant interviews and a representative survey of firm managers.

The study reveals that the comparative advantage index has declined from 13 in 2001-2005 to four in 2011-2013. It was also found that the average rate of employees working 80-hour weeks has decreased.

The study identifies several important health and social vulnerabilities associated with the RMG sector in Southeast Asia and South Asia. In particular, the study explores the relationship between health and work-related values, and the role of financial assets.

3 Child labor concentration in Yangon State

Despite Myanmar’s recent economic expansion, child labor remains a major concern. A 2014 census shows that almost one in five children between the ages of 10 and 17 are employed. However, the country lacks a comprehensive national law to protect working children. The government is negotiating with business owners to provide vocational training and health care for young workers.

The country has ratified the International Labour Organization’s Child Labour Convention (ILO C), and is also a member of the International Labor Force Survey, a report that tracks the prevalence of child labor worldwide. The ILO also works to strengthen capacity and promote change at the local level.

The government has also joined hands with the UN Task Force on Child Labour to monitor and combat child labor. A technical working group on child labor was set up in 2017. This project assisted the government to hold a National Consultation Workshop on child labour in 2017.

The ILO also has a local program in Myanmar that has reduced child labor by 55 percent in three pilot areas over the past three years. In addition, a new initiative called My-PEC has had a significant impact on the country. The project has helped the government draft the terms of reference for a technical working group on child labour.

A new organization could be created to supervise and monitor progress made by My-PEC. The project is scheduled to end in December 2021. Its main purpose is to increase the rights of child workers and improve education services for them.

In the short term, the ILO hopes to eliminate the most harmful forms of child labor. In the longer term, the ILO wants to achieve greater compliance with international standards and to implement local initiatives that promote the rights of working children.

4 Shortlisting the most economical Laos garment suppliers and exporters

Choosing the most economical Laos garment suppliers and exporters is a challenge. This is because the cost of production in Laos is higher than in other countries. This is due to the high unit cost of production, and the low labour productivity.

The textile and garment industry in Laos is an important sector of the economy. It employs more than 25,000 workers and generates foreign exchange. However, the industry is losing competitiveness. Hence, it is important for the government to support the sector through improved skills development and efficient management. The garment industry can also contribute to poverty alleviation.

The main bottleneck is the labour shortage. The majority of workers in the textile and garment industry are women. Most factories rely on orders from third parties.

The low wages and the lack of training and skills development affect worker productivity. The industry needs to diversify its product mix and improve worker skills. It is also crucial to increase cooperation with other garment producers in Southeast Asia and larger companies in the region.

To help develop the garment industry, the Ministry of Commerce should conduct consultations with the Chamber of Commerce and Industry, as well as local factories. The government should also review the current labour law to promote better business operations.

To improve the supply chain, the Laos government should improve the import procedures of raw materials. It should also provide prompt service for the export of ready-made garments. It should also negotiate bilateral agreements with clothing importers.

The garment industry should also improve its marketing activities. It should train workers on site. It should build design centres to increase capacity.

The garment industry should collaborate with the Government to develop vocational training institutes. It should also create merchandising centers to enhance the capacity of the Laos garment industry.

5 Volza’s benefits for Laos garment manufacturing companies

Despite the advantages that Volza offers to Laos garment manufacturing companies, they still face several challenges. This includes low labour productivity and low worker skills. These are factors that affect the added value of the products produced.

Another challenge is the lack of supporting industries. This has hindered expansion. To overcome these challenges, the Lao garment industry needs to improve its upstream industries. It also needs to collaborate with regional garment producers. To do so, it needs to improve its workforce skills.

The main bottleneck in the garment industry is labour. Workers must learn new skills when they enter new production settings. They must be trained on-site. During training, they need to learn how to use certain tools and equipment.

One of the reasons for the slowdown in the Lao garment industry is the decline in world market demand. The industry’s comparative advantage index declined from 13 in 2001-2005 to 4 in 2011-2013.

This decrease in comparative advantage is likely to disrupt workers’ skill development. Consequently, the profit margin will also be decreased. However, the garment industry will still be able to compete in the global market.

The Lao textile and garment industry is a key sector in the Lao economy. It produces more than 25,000 jobs. It also plays an important role in poverty alleviation.

While the Ministry of Commerce promotes exports, it does not have enough funds to do so. To facilitate trade, government support is crucial. For this reason, Laos should speed up its WTO accession process. The Lao government should improve its import procedures for raw materials. It should also negotiate bilateral agreements with clothing importers. It should also increase the prompt service for the export of ready-made garments.

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment

This year, we have found that many international buyers are seeking new suppliers based in nations outside of China and Thailand to purchase many goods and products, including uniforms, workwear, reusable cloth face mask, and protective clothing.

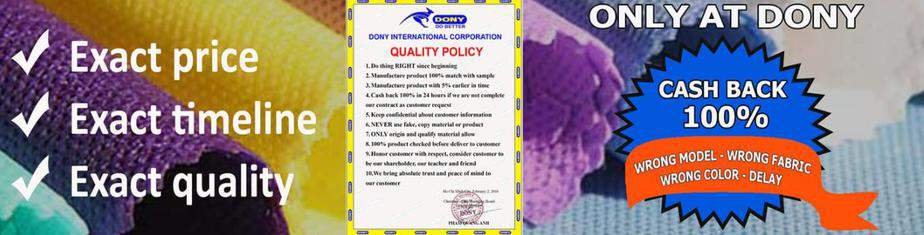

At DONY Garment, we are proud to welcome international customers, especially those based in the US, Canada, the Middle East, and the EU market to discover the professional production line at our factory in Vietnam.

We guarantee our products are of the highest quality, at an affordable cost, and easy to transport across the world.

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment