Despite the economic recession in Jordan, there are still some companies that can make some great garments. You just need to know where to look. Below is a list of some of the top garment manufacturing companies in Jordan.

1 Lotus garment

Founded in 1996 in Cairo, Egypt, Lotus garment manufacturing company is one of the most prominent garment manufacturing firms in the Middle East. It produces clothing for both men and women.

It is known for its innovation in men’s underwear, socks, home wear, and denim. The firm is also known for its quality jeans, which are well-known worldwide. It has built strong relationships with US outfits, such as Walmart and Gap.

The company’s production output was estimated at 120 million garments in 2020. The firm has a turnover of 610 million US dollars and employs 30,000 people from across the world. It operates 12 factories and 7 satellite units. Its total production capacity is 450,000 to 500,000 garments per day.

Jordan’s garment industry has expanded in recent years, and many positive factors have been attributed to it. However, there are several challenges that the sector is facing.

Labour problems in the textile and apparel industries are growing, and workers are demanding higher wages and improved health insurance coverage. The government is taking steps to address the situation. It has established vocational training programs to help workers become more skilled. It has also introduced a five-year national program of economic reform.

The country has also signed free trade agreements with the United States and the European Union. This has improved access to the American market for both the United States and Jordanian textile and apparel manufacturers.

2 Alextex

Among the top garment manufacturing companies in Jordan, Alextex is a leading exporter of high quality, ready-made apparels. They manufacture a variety of products including knitted garments for ladies, underwear, fleeces, shirts, and socks. The company provides a range of products at a reasonable price.

The textile and apparel sector of the Hashemite Kingdom of Jordan is a crucial part of its economy. It generates a significant share of its exports, a contribution of over 20 percent of its Gross Domestic Product. Its industry is a key component of its economic reform program.

The booming garment sector in Jordan has created a strong local fashion designer scene, and the country is becoming increasingly popular as a destination for luxury apparel. In addition, the textile and apparel sector holds a lot of potential for the country’s economy. However, there are several challenges that face the sector.

One of the biggest challenges facing the sector is cost management. In addition, the sector is facing competition. In order to advance, the industry must shift from bulk supplying to producing more value-added products. Moreover, it needs to improve its ability to attract foreign investment.

Towards that end, the government has adopted a comprehensive five-year national program for economic reform. The goal is to create more domestic jobs and improve the country’s labor force. The program also aims to provide vocational training programs for Jordanian workers.

3 CFAI

CFAI, or Classic Fashion Apparel Industry, is the largest garment manufacturer in the Middle East. Its five factories are located in Al-Hassan Industrial Estate and it also has two plants in the Cairo region. It produces over 77 million garments every year. The industry has a turnover of US $ 1.1 billion, and employs over 30,000 workers.

The garment sector has been a growth driver in Jordan for the past fifteen years. It has benefited from numerous free trade agreements with the United States, Europe and other countries. However, in recent years the industry has faced challenges. Increasing oil prices and a lack of natural gas have contributed to slower economic growth. The influx of 1.3 million Syrian refugees has exacerbated the situation. The government has tried to address the problem by offering vocational training programs to Jordanian workers.

However, many factories are facing labour problems and workers are demanding higher wages. They are also demanding more health insurance coverage. The Ministry of Labour has urged employers to reduce their reliance on foreign workers.

The textiles and clothing industry is the second-largest contributor to Jordan’s GDP. The government has set up a five-year national program to help the industry grow. It is also trying to attract foreign investment in the textile and apparel sector.

The IMF has approved a three-year Stand-By Arrangement with the Jordanian government to help with financing. This project is designed to improve the environment for the textile industry. It aims to train workers on international best practices and to qualify them for global markets.

4 LTE

Currently, Jordan is one of the most advanced countries in the world when it comes to garment manufacturing. The country’s textile and apparel industry is a huge engine for the economy. It is also a major node in the global apparel supply chain. However, there are numerous challenges that the sector is facing.

The Ministry of Labour has urged employers to reduce the dependency on foreign labor. It has set up a five-year national program for economic reforms. This includes a focus on rural poverty in the country. In addition, the government has established 14 Qualifying Industrial Zones to help grow the apparel industry.

During the past decade, the textile and apparel sector has made significant strides. However, there are still some concerns regarding labour issues. These include the legal status of migrant workers, wage theft, and violations of workplace rules. These are especially problematic for women, who are often excluded from the workforce after marriage or during their childbearing years.

The government has introduced a satellite unit model to help provide decent work opportunities to Jordanian women in the country’s rural areas. The model has been successful in bringing more than 4,700 women into the formal labour market.

However, the satellite garment units still face challenges in terms of profitability. The units have to be transformed into sustainable businesses. Moreover, more effort needs to be put into establishing public-private dialogue to achieve the core mission of the satellite unit model.

5 Vogue velocity and apparel

Despite the fact that the country has a rich textile and apparel manufacturing legacy, the nitty gritty remains under the radar in terms of government attention and funding. The apparel industry is home to over 500 companies, with most of them located in the greater Amman region.

This is an opportunity ripe for the taking, especially with the country’s recent approval of a five-year national program for economic reform. In addition to the usual suspects, Jordan also attracts some foreign investment thanks to its proximity to the lucrative Gulf markets of Kuwait and Qatar.

In particular, the most exciting developments have taken place in the Aqaba region. The aforementioned city is the epicenter of Jordan’s eastern seaboard. This is where most of the nation’s apparel exports go. It is also the source of the largest share of the country’s GDP. It is estimated that the nation’s garment industry is worth nearly $3.5 billion, and accounts for more than a third of the country’s total exports.

The aforementioned city is home to a number of notable companies, including Classic Fashion, which is the largest apparel manufacturer in the Middle East and contributes over 30 percent of all Jordanian garment exports. Another company that is worth a mention is El Ghannam, a major name in the Egyptian textile industry. While it is not exactly the next best thing to a local firm, its high-end terry towels are no slouches. Besides, it is among the fastest suppliers to the East Coast.

6 MENATEX

MENATEX, the Middle East and North Africa Textile and Clothing Programme, supports small and medium-sized enterprises in the textile and apparel industry. The program shares best practices, fosters collaboration, and strengthens regional supply chains. In Jordan, the textile and apparel sector contributes 27.5 percent of the country’s total exports.

The country’s garment sector has made great strides in recent years, especially in mitigating the critical lack of skilled workers. However, it faces numerous challenges. These include rising costs and a depressed domestic market, which has reduced capacity building and local sales. In addition, factory workers have been demanding improved health care coverage and higher wages.

The government of Jordan has implemented a series of free trade agreements with various countries, including the United States. It has also signed several free trade agreements with the European Union, Morocco, and other countries.

The Jordan-United States Free Trade Agreement was signed in 2001, and went into effect in February 2006. The FTA has facilitated duty-free access to the United States, which has helped Jordanian manufacturers gain access to the US market.

The apparel and textile sector is a vital engine of the economy. It has contributed 8.1 percent of the GDP. It is the country’s top export sector. It is also a key contributor to the economic development of the country. In terms of growth, the sector has grown steadily since 2010.

While the textile and apparel industry in Jordan is booming, it faces many challenges. The main challenge is attracting and training a skilled workforce. This will require a multi-pronged approach that includes creating incentives for companies to invest in their workforce, enhancing the skills of mid-level management, and providing financial assistance to factories for worker training.

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment

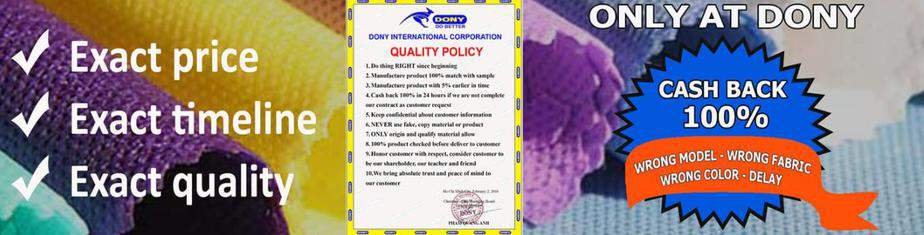

This year, we have found that many international buyers are seeking new suppliers based in nations outside of China and Thailand to purchase many goods and products, including uniforms, workwear, reusable cloth face mask, and protective clothing.

At DONY Garment, we are proud to welcome international customers, especially those based in the US, Canada, the Middle East, and the EU market to discover the professional production line at our factory in Vietnam.

We guarantee our products are of the highest quality, at an affordable cost, and easy to transport across the world.

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment