Currently, Botswana has a total of 62 garment manufacturing companies that operate across the country. Whether you are looking to purchase products or have your products manufactured in Botswana, there are several things you should keep in mind. Listed below are a few of the important factors to consider when you are looking for a manufacturing partner in the country.

1 High tariffs on textile and footwear inputs

Traditionally, the textile and clothing industry has benefited from high tariffs on imported inputs. These tariffs encourage the production of local products. They also provide jobs for the less skilled, thus alleviating poverty. The textile and clothing sector is a vital part of Botswana’s economic interests. The sector consists of knitted jerseys, cotton face cloths, denim jeans, kitchen towels and bedding.

The apparel industry has faced challenges since phasing out the FAP. The World Trade Organization has also restricted import substitution policies. In addition, the global economic crisis resulted in thousands of job losses in the garment manufacturing sector. Consequently, the garment industry has been challenged to increase its production and compete in the world market.

However, it is important to note that the reduction of the average applied tariff rate on apparel products is still a far cry from the reduction of the average applied tariff rates on all goods. This is because complex social and economic factors affect the reduction of the average applied tariff rate on the apparel industry.

One of the most important developments for the TC sector in the SACU region was the introduction of the Duty Credit Certificate Scheme (DCCS). It provided exporters with tax free subsidies. It was phased out after twelve years.

The TC industry also enjoyed a boost in exports from preferential trade agreements like AGOA. These agreements are crucial to the development of any country.

2 Suspension of AGOA from January 2022

Earlier this year, the United States announced that it would be suspending Ethiopia from the African Growth and Opportunity Act (AGOA) program. This is a preferential trade agreement that provides duty-free access for sub-Saharan African manufacturers to the United States market. The suspension will affect Ethiopia’s textile industry, which supplies global fashion brands.

The AGOA was signed into law in May 2000 by former US President Bill Clinton. The program is designed to remove trade barriers by incentivizing African governments to liberalize domestic markets. The program covers 6,500 product tariff lines. It also covers agricultural goods, footwear, wine, motor vehicle components, and steel.

The program is set to expire in 2025. The United States has recently determined that the eligibility requirements for Ethiopia, Guinea, and Mali will no longer be satisfied. This includes commitments to human rights, constitutionality, and political pluralism. Depending on the country’s situation, the administration can either reinstate its eligibility, or discontinue its eligibility.

The United States cited recent human rights abuses and the failure to defend human rights in Ethiopia. It also noted the ongoing civil war in the northern Tigray region of Ethiopia. The country’s Trade Ministry said it was “extremely disappointed” with the decision.

The AGOA’s TPSC Subcommittee will review comments and make recommendations to the President. The subcommittee will encourage public participation via written submissions. The subcommittee will not hold an in-person hearing.

3 Trends in exports during the period 2000-2015

Historically, the textile and apparel sector has been the backbone of the economic growth of Botswana. It was a key contributor to the economy of the country, and it helped to provide semi-skilled and unskilled employment for women and a revenue stream for the government. However, the sector has faced challenges in recent years.

The global economic crisis of 2008/09 was a serious blow to the garment industry. In fact, thousands of jobs were lost in the sector. This led to the development of a special support program for the sector. The program was designed to allow smaller exporting firms access to a subvention.

These subsidies were aimed at increasing the competitiveness of the industry, and lowering the costs of production. The incentive payments were based on the level of benefits received by the firm, which included the value of the goods exported.

After the collapse of Caratex in 2009, the TC sector faced a major crisis. The government decided to bailout the sector, allowing the sector to recover from its recession. Unfortunately, the support program did not last long, and the apparel industry continued to suffer.

During the interim period of the General Export Incentive Scheme (GES), tax-free subsidies were provided to the TC industry. The subsidy system was intended to encourage the export of TC products. It was designed to reward firms that added value to their products.

4 Vertical integration

Despite its name, vertical integration is not always a bad idea. While some companies may struggle to handle the operational complexities of increased scope, others have been able to harness the power of this supply chain strategy.

Vertical integration is the process of combining the production of various goods and services into one streamlined system. It allows companies to secure their distribution assets while making more competitive offerings. Often, this is accomplished by outsourcing part of the value chain.

There are two main types of vertical integration – backward and forward. In the former, a company owns the value chain, which includes a variety of operations, but relies on external service providers for other aspects. This strategy is a good option for companies that need to produce manufactured components, but want to maintain ownership of the manufacturing assets.

In the latter, the company is involved in product development before reaching the end consumer. This is usually done through a subsidiary that operates in different parts of the supply chain.

There are many risks associated with vertical integration. These include economies of scale, possible anti-trust regulations, and the difficulty of entering new markets. These challenges should be considered before committing to a restructured supply chain.

Choosing a strategy with the right mix of elements can help ensure a positive outcome. For example, a forward integration model using ownership of assets is similar to franchising, but maintains the control of a company’s partners by owning their intellectual property.

5 Ability to source new materials

Despite the African Growth and Opportunity Act (AGOA) providing duty-free access to the US market, many local textile manufacturers have given up on exporting to the United States. Instead, companies are choosing to stay in stronger markets. They are concerned that the AGOA extension will affect their business.

Botswana has a vibrant clothing industry that employs more than 3,000 people. However, the local sector faces a number of challenges, including high operational costs, lack of finance, and uncoordinated niche markets. These issues are not helped by the fact that the country is landlocked and has limited transport capacity.

The Government of Botswana has taken a number of initiatives to boost the local clothing and textile sector. These include a stimulus package designed to help companies improve productivity and efficiency, as well as help them get their wages paid on time. It also lists textiles as one of its priority sectors in the Revised National Export Strategy.

While the government has promoted the sector, it has resisted pressure from local manufacturers to provide direct export incentives. It is also focusing on opening up regional markets for producers.

In order to be able to benefit from the AGOA, local manufacturing companies must source raw materials locally. The cost of complying with the program’s requirements has also been a major concern for manufacturers.

The future of the AGOA program is expected to be discussed at a Washington meeting later this month. In the meantime, the Ministry of Trade and Industry has pushed for an extension of the third-country provision under the act. It is hoped that this will allow textile exporters to continue enjoying the benefits of duty-free access to the US market until September 2015.

The Botswana Textile and Clothing Association (BTCA) was created in January 2010 to promote the sustainable development of the sector. Its mission is to enhance the competitiveness of the clothing and textile industries in the Botswana and global markets.

6 Labor costs

Historically, the apparel sector in Botswana has been a pillar of the country’s economic interests. However, over the past twenty years, the industry has faced a number of challenges. Among them are a lack of competitiveness and operational inefficiencies. Its success depends on the entrepreneurial prowess of the private sector and local government policies.

The export textile sector is growing at a rapid pace. Moreover, foreign direct investment has played a vital role in promoting the growth of the industry. Nevertheless, there is a need to develop a stable investment climate. In addition to that, the risks associated with the export market need to be addressed.

The sector has been benefited by preferential trade agreements and export incentives. However, the sector also faces challenges such as low productivity and a high cost of raw materials.

In 2010, the African Growth and Opportunity Act (AGOA) granted “lesser developed beneficiary” status to Botswana, enabling it to export TC products duty free to the United States. AGOA also helped the textile and clothing sector to create 50,000 jobs.

In 2008, the Bureau of Industrial Development and Planning (BIDPA) conducted a study on the tariff structure of the SACU region. It discovered that although there are seventy-six ad valorem lines, only 126 are duty free. The rest attract mixed tariffs. In addition, a total of 581 textile input lines represent eighty-two percent of the country’s total tariff lines.

7 Afro-Fashion Garments

Founded over three decades ago, Afro-Fashion Garments is one of the pioneers of garment manufacturing in Botswana. The company specializes in producing high-quality garments for both men and women using various fabric types such as cotton, denim and polyester blends. They also offer embroidery services with their own equipment.

8 Kgosi Apparel

Established more than 30 years ago by award-winning fashion designer Lesedi Kgosiemang Masekela , Kgosi Apparel has gained an excellent reputation among customers due its stylish yet affordable designs that cater to every taste and budget. Furthermore, they also provide a range of cutting edge materials such as microfiber fleece and performance wear fabrics that are perfect for sportswear items like shorts or tracksuits.

9 Gaborone Apparel Factory

This apparel factory is known for its fast production times thanks to its advanced technology machinery which includes laser cutters and computerized embroidery machines capable of producing intricate patterns with ease . In addition , they also offer custom design services which allow clients to tailor their products according to individual needs .

10 Tlhokomelo Textiles

Situated closeby Gaborone , Tlhokomelo Textiles is renowned for being one of the most experienced textile companies on the continent . Not only do they manufacture clothes from African fabrics but they are also able increase efficiency by leveraging modern technologies like CAD/CAM systems . As a result , this helps them create unique pieces that meet international standards without compromising quality or cost effectiveness .

11 Masana Uniforms & Workwear Solutions

For those who are searching for workwear items tailored specifically towards safety regulations then look no further than Masana Uniforms & Workwear Solutions ! Their wide selection includes uniforms reflective vests, jackets, overalls etc all made from durable yet comfortable materials ideal even if used under extreme conditions (e g mining)

12 Gaborone Clothing Manufacturers

Based in Gaborone, this company provides a wide range of services related to clothing production and design. They offer different types of fabrics for their clients as well as custom designs for those who want something unique for their product line.

13 Afro Tekstiles

This company specializes in tailoring high-quality garments from African textiles and materials such as kente cloths from Ghana and wax prints from Nigeria among others . Their expertise lies in creating unique pieces with bold colors that are sure to make anyone stand out from the crowd.

14 B’Nai Textile Solutions

Founded by two entrepreneurs with extensive experience working with textile mills around Africa, this company produces high-quality fabric using modern machinery combined with traditional weaving techniques sourced locally by them or their suppliers across Botswana.. They also provide pre-made patterns and kits so customers can easily create their own designs without having to source any additional items they may need themselves..

15 Mohalenyane Phohleli Garments & Apparels

Located near Francistown, this family owned business has been providing quality readymade clothes since 1995 . The strength lies not only on quality craftsmanship but also on specialised services like custom made orders , alterations , embroideries , logos etc which makes them one of most sought after manufacturers when it comes to promotional wear or uniforms .

16 Ditshupo Fashions

Located near Lobatse ,this company manufactures both men’s casual wear and sportswear .They specialize mostly on t -shirts but they do provide other styles too like shorts , jackets etc all tailored according customer needs .Their team includes experienced designers who can help bring your ideas into life quickly !

17 Mokgosi Fashion Studio

Specialized more towards women’s clothing line this studio offers customized bridal gowns along side evening wear range including prom dresses & cocktail dresses .Their work brings together modern trends combined with traditional inspiration from local culture making them a go -to place if you’re looking something special yet stylish !

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment

This year, we have found that many international buyers are seeking new suppliers based in nations outside of China and Thailand to purchase many goods and products, including uniforms, workwear, reusable cloth face mask, and protective clothing.

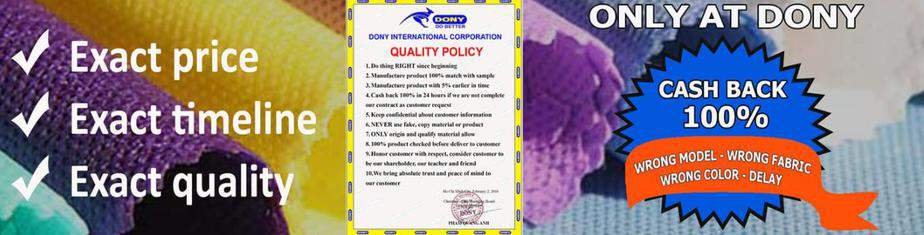

At DONY Garment, we are proud to welcome international customers, especially those based in the US, Canada, the Middle East, and the EU market to discover the professional production line at our factory in Vietnam.

We guarantee our products are of the highest quality, at an affordable cost, and easy to transport across the world.

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Dony Garment Vietnamese Garment Factory Supplier – Apparel Clothing & Textile Manufactured. Private label clothing Produce women, men, children baby wear – Casual Clothing, Uniform, Workwear

Henry Pham (Pham Quang Anh), CEO of DONY Garment

Henry Pham (Pham Quang Anh), CEO of DONY Garment